March 2009

Armed Virginia Sloop, pt4

24 - March - 2009 - 21:38

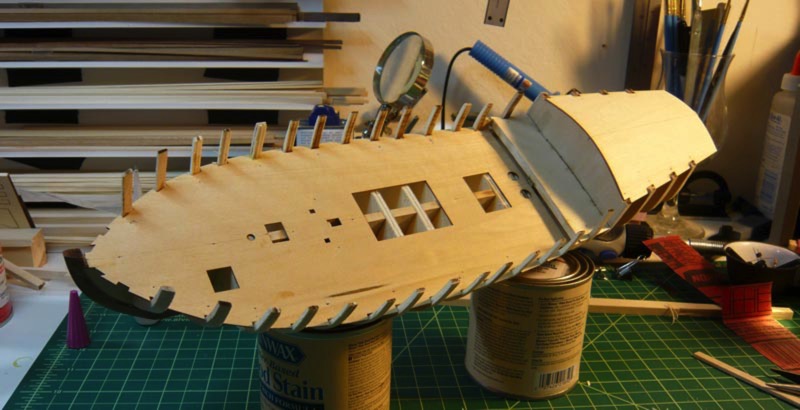

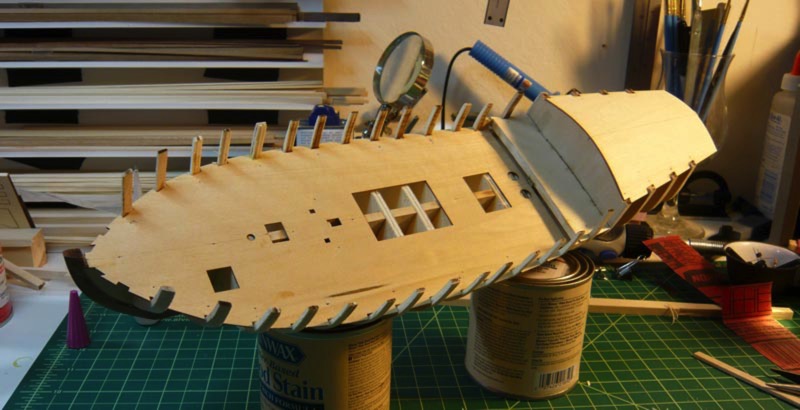

I haven't had much time recently to work on the ship, but I have managed to get the rear structure built and the front filler pieces cut and fit and sanded. Both ends took a good deal of shaping and sanding, and therefore took a bit longer than I was expecting.

I highly recommend getting a Dustbuster for your work area, if you don't already have one. I have found that having a little vacuum like that around allows me to really keep the amount of sawdust and wood shavings to a minimum. I'm hoping, in the long run, that this will save me a good deal of cleaning later. When I built the little speedboat (lower on the page), I ended up with a coating of fine sawdust all over everything in the room, which was a real task to clean up.

Here are a few photos of where I currently am. I am also goofing around with the picture layout thing. It's a bit clumsy to use.

I highly recommend getting a Dustbuster for your work area, if you don't already have one. I have found that having a little vacuum like that around allows me to really keep the amount of sawdust and wood shavings to a minimum. I'm hoping, in the long run, that this will save me a good deal of cleaning later. When I built the little speedboat (lower on the page), I ended up with a coating of fine sawdust all over everything in the room, which was a real task to clean up.

Here are a few photos of where I currently am. I am also goofing around with the picture layout thing. It's a bit clumsy to use.

Mega Model Railway in Germany

23 - March - 2009 - 14:36

I'm not really into the model railroad thing, but the shear scale of this one is impressive.

Miniatur Wunderland

Be sure to watch the video!

Miniatur Wunderland

Be sure to watch the video!

Armed Virginia Sloop, pt3

15 - March - 2009 - 21:29

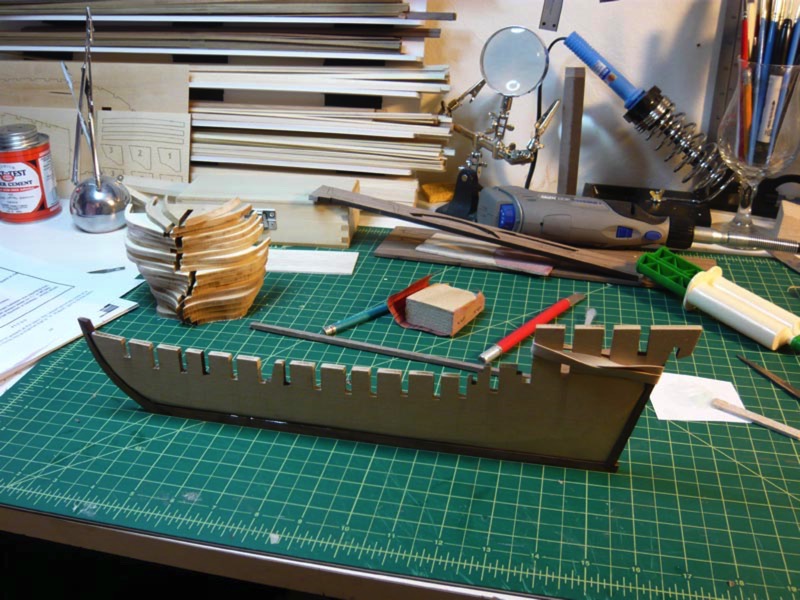

At long last I have an update for this build. I've managed to get most of the frame of the hull assembled. The actual assembly was pretty quick (it's easy to glue things together), but once things were assembled, there was a great deal of sanding and fitting to do to make life easier inlater steps. Apparently, this is called 'fairing' the hull. It mostly consists of taking a scrap strip of wood and laying it along the outside of the hull so that one can see which ribs stick up higher or are lower than the rest. Then one must sand down the high ribs or glue on strips of wood for the low ribs. Then there is more sanding, a bit of sneezing (turns out my nose doesn't like saw dust very much), then a bit more fitting and sanding. There is also a great deal of accidental breakage of tiny wood parts, followed by loud cursing and then some reglueing of those parts.

This is also where the course that I am following differs a bit from the instructions that come with the kit. The course had me attach the sub decking (just a thin sheet of basswood) before framing the rear cabin, in order to give strength to the whole ship. While the instructions suggested putting little support pieces between the ribs to give it strength, and doesn't have me put on the subdeck until after all the rest of the framing is done. I can appreciate that the course method saves me quite a bit of time that would have otherwise been spent cutting little blocks of wood, but I like to think I made up for it in time spent glueing pieces of that thin deck back on after I managed to break them off while working on a different part of the hull. ;-)

All in all, I think I've got the hull faired and am ready to move on to framing up the rear cabin of the ship. There is probably a better term for that part of a ship, but I can't remember it at the moment :)

Anyhoo, here are some photos of where I am now:

This is also where the course that I am following differs a bit from the instructions that come with the kit. The course had me attach the sub decking (just a thin sheet of basswood) before framing the rear cabin, in order to give strength to the whole ship. While the instructions suggested putting little support pieces between the ribs to give it strength, and doesn't have me put on the subdeck until after all the rest of the framing is done. I can appreciate that the course method saves me quite a bit of time that would have otherwise been spent cutting little blocks of wood, but I like to think I made up for it in time spent glueing pieces of that thin deck back on after I managed to break them off while working on a different part of the hull. ;-)

All in all, I think I've got the hull faired and am ready to move on to framing up the rear cabin of the ship. There is probably a better term for that part of a ship, but I can't remember it at the moment :)

Anyhoo, here are some photos of where I am now:

Armed Virginia Sloop, pt 2

03 - March - 2009 - 21:56

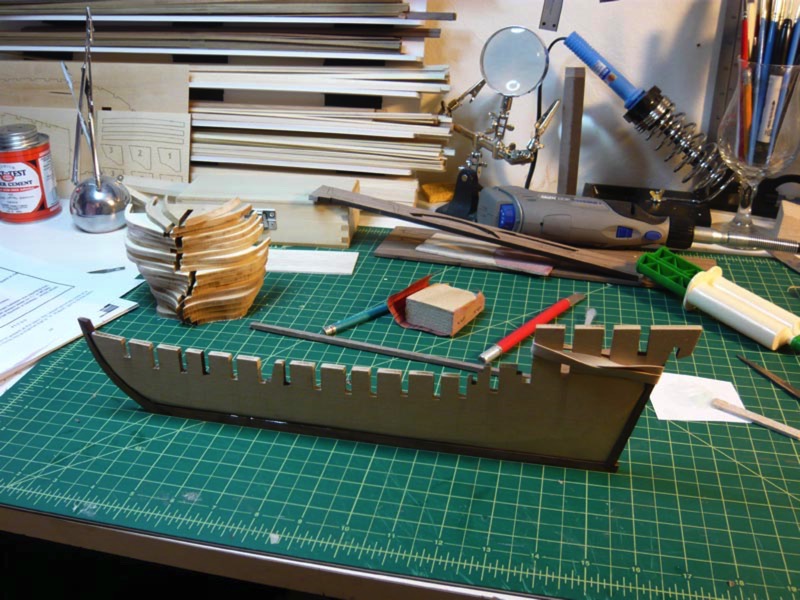

I've gotten a little start on the ship. Mostly some cutting, sanding and fitting. I cut out the keel, and all the bulkheads, sanded their edges, and sanded the joints a bit until they all fit together. I've also received the practicum course mentioned below, and have been reading and following that.

I did some cutting and beveling on the center keel and have just started to actually attach some pieces together. You can see below, I've glued the walnut keel pieces to the edges of the basswood center keel. Next comes more cutting and carving and fitting, as I need to be sure that the groove into which all the planking will later fit is the proper size and angle before all the bulkheads get glued in place.

On a side note, today I received the pegboard that I order a few weeks ago. So, I spent some time this evening organizing and generally pegging things up on my board. Really, the goal was just to get many of my tools up off the desk, giving me more work space.

This past weekend, I also spent a few minutes making myself a little foamcore shelf sort of thing that I could put all the plank wood on, to keep it out of the way and to keep it from getting broken. In the below photo, you can see the little shelf below the left side of the pegboard.

Next post will hopefully have the bulkheads in place, and the shape of the ship will actually be a bit more visible.

I did some cutting and beveling on the center keel and have just started to actually attach some pieces together. You can see below, I've glued the walnut keel pieces to the edges of the basswood center keel. Next comes more cutting and carving and fitting, as I need to be sure that the groove into which all the planking will later fit is the proper size and angle before all the bulkheads get glued in place.

On a side note, today I received the pegboard that I order a few weeks ago. So, I spent some time this evening organizing and generally pegging things up on my board. Really, the goal was just to get many of my tools up off the desk, giving me more work space.

This past weekend, I also spent a few minutes making myself a little foamcore shelf sort of thing that I could put all the plank wood on, to keep it out of the way and to keep it from getting broken. In the below photo, you can see the little shelf below the left side of the pegboard.

Next post will hopefully have the bulkheads in place, and the shape of the ship will actually be a bit more visible.